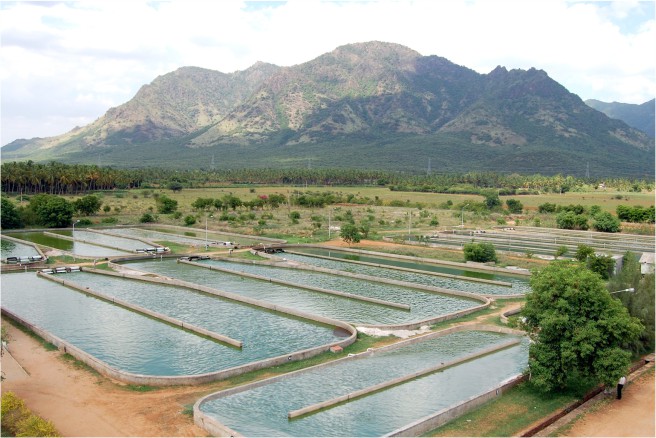

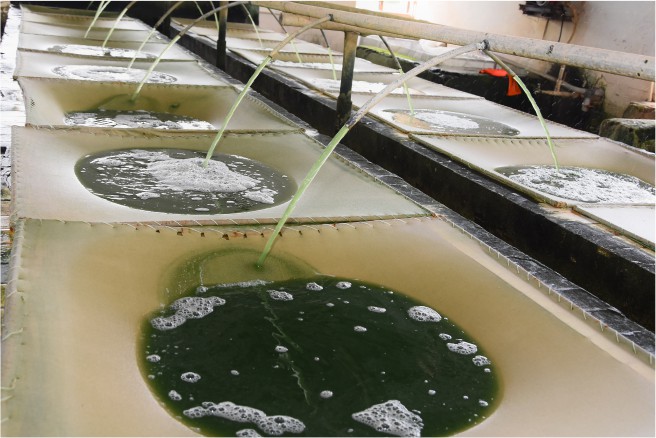

Manufacturing Facilities

With the prime focus of delivering quality products each time and on time, we have established robust mechanism to monitor and control the entire manufacturing process, from raw material extraction to standardisation of the final product. The processes are optimized to ensure that we achieve the required standardization of the bioactives and retain their bio-efficacy batch to batch.

We are committed to ensure that we are equipped with the latest technology and infrastructure in the space of both, the Manufacturing and Analysis so that we only deliver the highest possible quality phytoextracts and high pure actives to our clients. We pride in establishing transparency, trust and finished product excellence across our processes and its execution - from the sourcing to the finished goods. We meticulously document every process that has an impact on product quality and make it available for review by our clients.

Our Manufacturing Units